Different Types of Welding Joints and the Best Methods to Weld Them

When it comes to metal fabrication and welding, understanding the different types of welding joints is essential. The joint you choose directly affects weld strength, penetration, and the final product’s durability. At WCR Tools, we provide professional-grade welding accessories—including welding angle magnets, magnetic welding grounds, and regulator wrenches—to help you get perfect alignment, grounding, and gas flow for every weld joint.

In this guide, we’ll go over the five main types of welding joints, the best welding methods for each, and the tools that can make the job easier and more precise.

1. Butt Joint

A butt joint is when two metal pieces are placed end-to-end on the same plane. This is one of the most common joints in MIG welding, TIG welding, and Stick welding.

Best welding methods for butt joints:

-

MIG welding for mild steel and aluminum (fast and clean welds).

-

TIG welding for stainless steel or thin materials (precise and strong).

-

Stick welding for outdoor or heavy-duty structural work.

Tips for success:

-

Use a welding angle magnet to hold plates perfectly aligned.

-

For thicker metals, bevel the edges for deeper penetration.

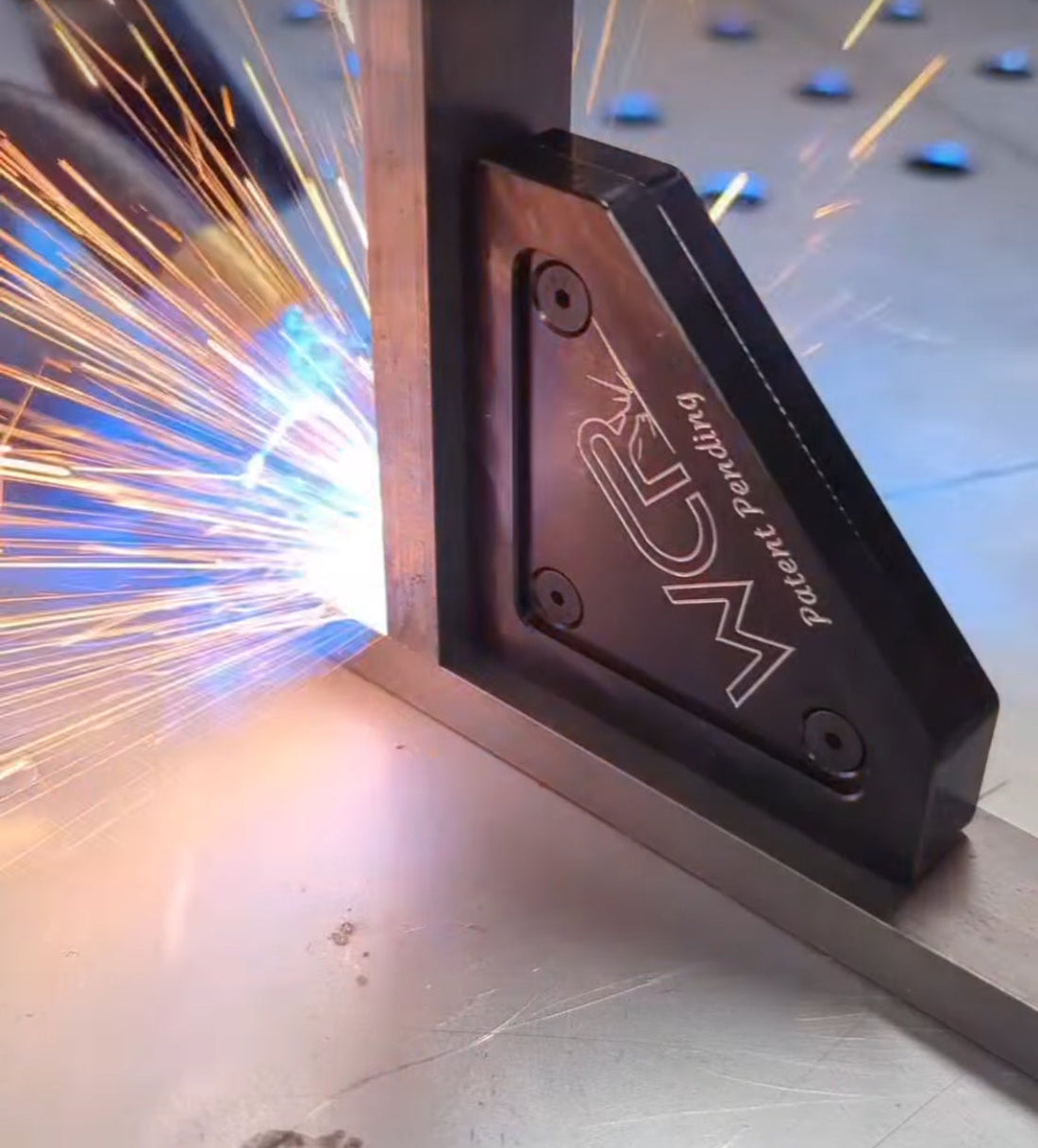

2. Corner Joint

A corner joint is formed when two metal pieces meet at a right angle, often used in frames, boxes, and sheet metal work.

Best welding methods for corner joints:

-

MIG welding for fast production and minimal cleanup.

-

TIG welding for neat, visible welds (like on furniture or custom fabrication).

Tips for success:

-

Use welding angle magnets to hold parts at 90° while tacking.

-

Choose fillet welds for strength, or fusion welds for aesthetics.

-

Keep your magnetic welding ground close to the weld area for better arc stability.

3. Lap Joint

A lap joint is when one piece of metal overlaps another, often used in sheet metal and thin plate welding.

Best welding methods for lap joints:

-

MIG welding for speed and efficiency.

-

TIG welding for thin, delicate materials.

-

Spot welding for sheet metal fabrication.

Tips for success:

-

Maintain proper torch angle to ensure penetration into both layers.

-

Use clamps or welding magnets to keep pieces tight during welding.

-

Avoid excessive heat to prevent warping.

4. Tee Joint

A tee joint is when one metal piece is positioned at a 90° angle to another, forming the shape of a “T”.

Best welding methods for tee joints:

-

MIG welding for fillet welds on structural steel.

-

TIG welding for clean, precise welds on visible projects.

-

Stick welding for heavy-duty, outdoor work.

Tips for success:

-

Use welding angle magnets for perfect perpendicular alignment.

-

Choose the correct weld size for load-bearing applications.

-

Keep weld bead consistent for strength and appearance.

5. Edge Joint

An edge joint is when the edges of two or more metal pieces are placed side-by-side and welded together.

Best welding methods for edge joints:

-

TIG welding for thin sheet metal.

-

MIG welding for light structural applications.

Tips for success:

-

Avoid overheating, as edges can burn through easily.

-

Use a magnetic ground clamp to improve arc stability.

-

For thin materials, a backer bar can prevent burn-through.

Choosing the Right Welding Joint and Method

Selecting the correct welding joint type and welding process depends on:

-

Material thickness

-

Type of metal

-

Required strength

-

Appearance of the weld

-

Working environment

At WCR Tools, we offer professional welding accessories to make every weld joint more precise and efficient, including:

-

Welding Angle Magnets for accurate positioning.

-

Magnetic Welding Grounds for stable electrical contact.

Final Thoughts

Mastering the different welding joints and their best welding methods will improve your productivity, weld quality, and final product durability. Whether you’re welding for fabrication, repair, or artistic work, having the right tools makes all the difference.

Visit WCR Tools to explore our full range of welding accessories designed for professionals and passionate welders alike.