Comparing MIG, TIG, Stick, and Laser Welding Machines: Which One is Right for You?

When it comes to welding, choosing the right machine isn’t just about the brand—it’s about matching the tool to the job. Whether you’re repairing farm equipment, fabricating custom metalwork, or running a production line, the type of welding machine you choose will impact quality, speed, cost, and efficiency.

Below, we break down MIG, TIG, Stick, and Laser welding machines—highlighting their strengths, ideal uses, and what you can expect to pay.

1. MIG Welding (Metal Inert Gas)

Best for: Beginners, medium-to-heavy fabrication, automotive work.

How it works: A wire electrode feeds continuously through a welding gun, with shielding gas protecting the weld from contamination.

Pros:

-

Fast and easy to learn.

-

High productivity for thicker metals.

-

Minimal cleanup compared to Stick welding.

Cons:

-

Not ideal outdoors—wind can disrupt the shielding gas.

-

Less control over delicate welds compared to TIG.

Typical Cost:

-

Entry-level hobby machines: $300–$700

-

Professional-grade MIG welders: $1,200–$3,000

-

Industrial units: $5,000+

Operating Costs: Moderate—requires consumable wire and shielding gas.

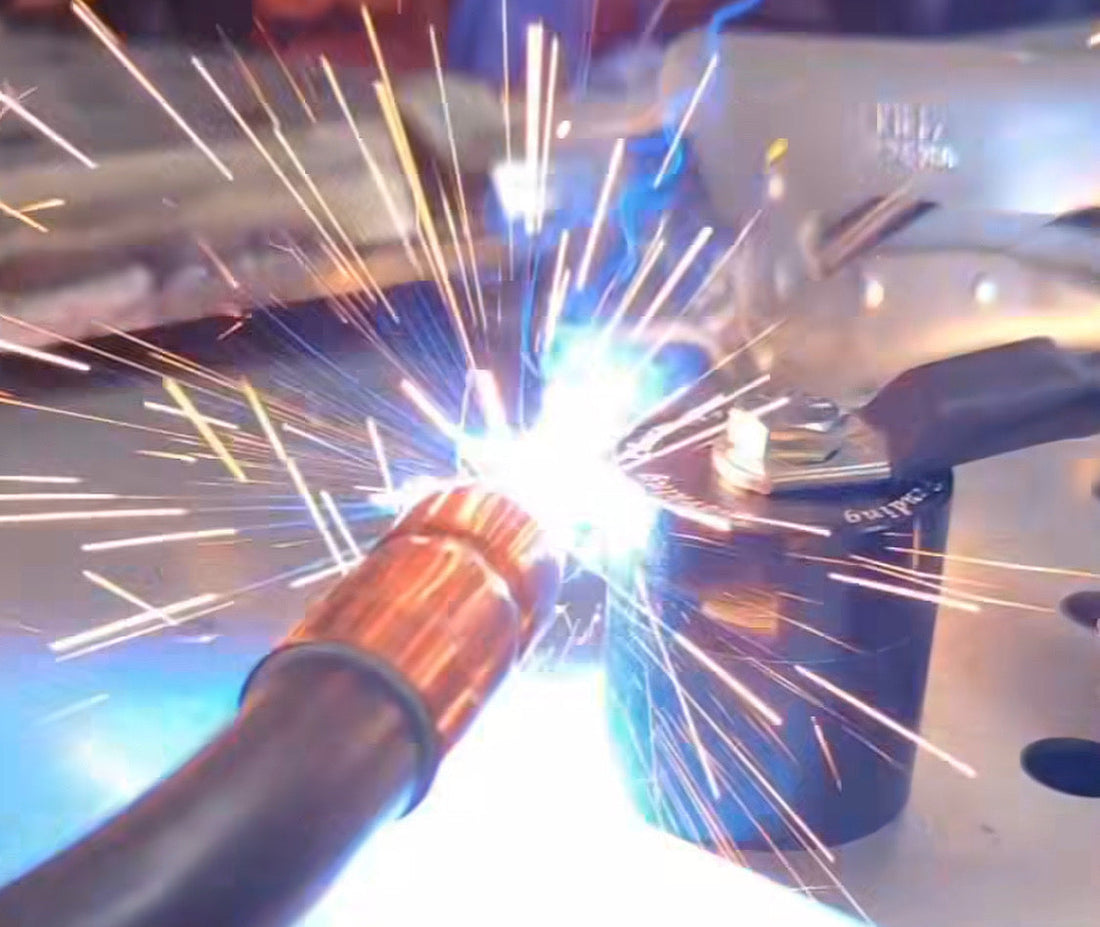

In this picture you can see the MIG welding torch in action. There is a nozzle where gas and wire come out from. This wire is fed onto the work by the machine while shielding gas is used to protect the weld from oxygen. The wire then makes contact with the grounded work which completes the electrical circuit and melts into and with the work.

2. TIG Welding (Tungsten Inert Gas)

Best for: High-precision, thin metals, stainless steel, aluminum.

How it works: Uses a non-consumable tungsten electrode with a separate filler rod. The welder controls heat and filler independently, producing extremely clean, precise welds.

Pros:

-

Exceptional weld quality—ideal for aerospace, food-grade, and artistic metalwork.

-

Works well on thin materials and exotic metals.

-

Minimal spatter.

Cons:

-

Slower process than MIG or Stick.

-

Requires more skill to master.

Typical Cost:

-

Entry-level TIG machines: $800–$1,500

-

Professional-grade TIG welders: $2,500–$6,000

-

Advanced AC/DC TIG systems: $10,000+

Operating Costs: Higher—shielding gas and tungsten electrodes needed; slower process means higher labor cost.

These are some 304 stainless steel exhaust hanger brackets I made using the TIG process. Careful heat and gas control allows for a very clean and consistent weld bead

3. Stick Welding (Shielded Metal Arc Welding)

Best for: Outdoor, heavy-duty structural work, repair jobs.

How it works: An electric current melts a consumable electrode coated in flux. The flux produces a gas shield and slag to protect the weld.

Pros:

-

Works well outdoors—even in wind or rain.

-

Simple, rugged machines.

-

No external shielding gas needed.

Cons:

-

More cleanup due to slag.

-

Less precise—more suited for thicker metals.

Typical Cost:

-

Basic Stick welders: $200–$500

-

Industrial Stick machines: $1,000–$2,500

Operating Costs: Low—only consumable electrodes needed.

Stick welding is definitely the dirtiest of the processes listed here. Make sure you wear your protective equipment any time you weld, but as sparks and fumes are especially prevalent during SMAW its even more important

4. Laser Welding

Best for: High-speed precision manufacturing, electronics, automotive, and medical device production.

How it works: Uses a concentrated laser beam to melt and fuse materials. Can be automated for ultra-precise welds with minimal heat distortion.

Pros:

-

Extremely fast and accurate.

-

Minimal distortion and no filler needed.

-

Can weld very thin or very hard materials.

Cons:

-

Very expensive upfront.

-

Requires trained operators and specialized safety measures.

Typical Cost:

-

Small benchtop laser welders: $15,000–$30,000

-

Industrial robotic laser welding systems: $75,000–$500,000+

Operating Costs: Low for consumables, but high for maintenance and operator training.

Cost & Application Comparison Table

| Welding Type | Ideal Use Case | Machine Cost Range | Operating Cost | Skill Level | Speed | Portability |

|---|---|---|---|---|---|---|

| MIG | Automotive, fabrication, general metalwork | $300–$5,000+ | Moderate | Easy–Medium | Fast | Medium |

| TIG | Precision, stainless, aluminum, exotic metals | $800–$10,000+ | High | High | Slow | Medium |

| Stick | Outdoor, structural, repair | $200–$2,500 | Low | Medium | Medium | High |

| Laser | High-end manufacturing, electronics | $15,000–$500,000+ | Low–High | High | Very Fast | Low |

Final Thoughts

If you’re a hobbyist or small workshop, MIG or Stick might be the most cost-effective choice. For precision fabrication, TIG shines despite the slower pace. And if you’re in mass production or high-end manufacturing, Laser welding—though costly—can offer unmatched speed and precision.

The right machine isn’t the one with the most features—it’s the one that fits your work, budget, and skill level.

A Note From Danny:

From my personal experience the best place to start is a MIG welding setup. While virtually everyone I have taught to weld wants to immediately jump to TIG, gaining the fundamentals on MIG welding will make the transition to TIG welding much easier. TIG will require you to have mastered torch stand off distance, travel speeds, and understanding how the puddle moves. I always call TIG welding "flying the helicopter because almost all your limbs are moving independently between controlling the footpedal, running filler rod, and controlling the torch, while MIG welding puts less variables in front of a welder. And dont sleep on MIG welds! There is nothing wrong with a good MIG weld despite what the ole instagram says!